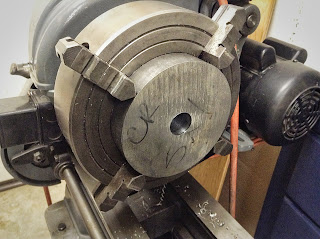

I started on the nozzle ring this morning. I drilled out the center, starting with a center bit and working up to a 1" diameter bit. The larger drill bits remove a lot of material quickly, but an inch is about the limit for my lathe. Next I'll bore out the center to the right diameter. Then I'll face it, cut the relief that the divergent section fits into, and index the holes for the six screws that hold the two sections together. Then I'll flip the piece. Once flipped I can finish it off to the correct diameter and cut the convergent section. Lastly I'll add the o-ring gland and index the twelve screw locations for the screws that hold it in the casing.

Friday, May 17, 2013

TR-1 MOTOR UPDATE

I started on the nozzle ring this morning. I drilled out the center, starting with a center bit and working up to a 1" diameter bit. The larger drill bits remove a lot of material quickly, but an inch is about the limit for my lathe. Next I'll bore out the center to the right diameter. Then I'll face it, cut the relief that the divergent section fits into, and index the holes for the six screws that hold the two sections together. Then I'll flip the piece. Once flipped I can finish it off to the correct diameter and cut the convergent section. Lastly I'll add the o-ring gland and index the twelve screw locations for the screws that hold it in the casing.

Subscribe to:

Post Comments (Atom)

.jpg)

No comments:

Post a Comment