I actually finished the motor casing prior to the nozzle, but here are the two pieces together. It was a conscience decision to complete the casing first so that I could get the most accurate measurement of the ID before starting on the nozzle. The ID in this case ended up being very close to the spec. and the nozzles actual OD ended up being 1.606". I will probably make the bulkhead a few "thou" smaller in diameter to make it a bit easier to install and uninstall in the motor.

Showing posts with label motor design. Show all posts

Showing posts with label motor design. Show all posts

Thursday, January 15, 2015

Monday, January 12, 2015

Amateur Rocket Motor Design

The 2.375" rocket motor is ready to test but I haven't had the opportunity to get out the test site. I have been feeling the urge to be doing some rocketry though and with that in mind I decided to build something. I chose something small. While the SStS project was immensely satisfying and a great educational experience it did lack a big part of what I enjoyed from my early days in rocketry. The thing i really miss is taking something from concept all the way through to completion, being involved with every step, and then actually getting out to the desert and launching the vehicle. It turns out that I had a rocket that I had promised to rebuild after it was lost over 8 years ago. That rocket was powered but Richard Nakka's C-400 motor, slightly modified to utilize KNSB, a Sorbitol based propellant versus Sucrose which the C-400 was originally intended to be fueled with. I came across this VCP design printout a while back. At the time it wasn't the largest rocket I had built or flown but it was definitely the highest performance one with a lot of attention to drag, weight, and construction details.

Here's a photo of its only launch. My brief blog entry of the launch can be found by clicking here.

As you can see by the photo, my daughters paint scheme won out over my own preference. I hope to document this build to a much greater extent than the first time around. With that in mind here are my initial design thoughts. The hope is to create a motor/rocket that is simple to construct, durable, and easy to prep for launch. I'm initially designing towards a Dextrose based propellant but am hoping to be able to use several of the other sugars available. Actually my notes indicate that the above launch used a propellant that was comprised of 50% Sucrose and 50% Sorbitol.

Casing design:

SRM output:

Here is my initial CAD:

Friday, October 24, 2014

Propellant testing (Dextrose, Sorbitol, Erythritol)

I've had a hard time finding time to post, but the good news is that I have been finding little bits of time here and there to continue working on rocket stuff. I went through and organized my garage/work space a while back which was good. I also when through my bins, range box, the stuff I haul out to a lunch and organized, took stock, and replenished on the things that I was out of. I also recently rebuilt a laptop and geared it towards rocketry so that all of the design, drawing, spreadsheets, photos, etc are centrally located. I have made a new motor case to use with my 2.375" motor to test Dextrose with. The motor was originally designed as an 8 segment KNER (erythritol based propellant). That test cato'd half way through the burn. I do still want to redo that test, but this time with a stepped core. After that test I reduced the segments to 6 and it was successfully flown, though the recovery left a little something to be desired. The motor got so hot that the while floating down on the parachute the lower half of the aeroshell (made of heavy cardboard) caught fire. It eventually fell away from the 'chute and came in ballistic. Fortunatly that nozzle didn't sustain any damage. Any way, the next time I manage to get out to FAR, I plan to fire this motor as a 4 segment and as a 6 segment motor, with some luck I may get the 8 segment motor ready as well.

Wednesday, September 3, 2014

TR-1 SRM update

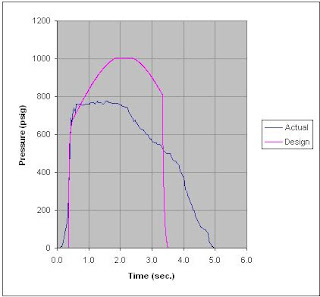

I ran the motor through SRM a few times playing around with

some of the numbers mostly because of

the switch from a Sorbitol based propellant to Dextrose based. Ultimately the only change I'm making is the

change in sugar type. This has a few

effects on the motor, all relatively minor.

The overall burn time of the motor is reduced by about 1/2 a second,

average thrust goes up a bit, and the MEOP goes up to 1200 psi from 1050

psi. The retention screws are designed

to sheer at 1800 psi so the design safety factor is still a fairly conservative

1.5.

Monday, May 13, 2013

TR-1 PROPELLANT SEGMENT DESIGN

I plan to use a 4" ULINE mailing tube as the casting tube/inhibitor for this motor. This particular tube has a wall thickness of 0.080" and allows for a bit of insulation to fit between the propellant segments and the casing wall. The motor is designed to use a propellant grain consisting of six segments. Each segment should weigh approximately 4.75 lbs (2.15 kg) for a total propellant load of approximately 28.5 lbs (13 kg).

TR-1 ROCKET MOTOR UPDATE

It been almost exactly one year since I started this motor...far too long. SStS has been going very slowly and in spite of some recent progress, I suspect that the the way forward will continue to be a slow progression. Back when I started getting really involved with amateur rocketry thirteen years or so ago, I was designing, making, testing, and flying much more frequently. I think in those early days, once I joined the Reaction Research Society there was so much excitement in going to the launches. The first event that I went to included zinc/sulfur, LOX/kerosene, HTPB, and sugar . Within the next few months I saw many more of those and added steam, HTP, and a variety of hybrids, good times. I don't know that I can get back to that level of activity anytime soon, but Theo definitely enjoyed the desert, the rockets, and the people so we should make a point to go more than once a year. With that in mind I'm making a conscious effort to finish the TR-1 motor ASAP.

Here is the next part to be made.

This is a fairly heavy motor, but it won't matter. With 1000 lbs of thrust there is no doubt in my mind that it will get itself off the ground when it's time to. The purpose is to build something relatively simple and at low cost, and to sharpen my skills before moving on to a larger project that I've been toying with for the past 10 years or so. There is some excess material in this design, so the part could go through a weight reduction process, but there is really no point for a static test.

Wednesday, June 6, 2012

Hermes Solid Rocket Motor

I bought number of Thiokol publicity/advertising brochures on ebay a while ago. There are a lot of interesting photos including the one above that shows Harold W. Richey posing with the "milestone" Hermes rocket motor which was fired in December of 1951. In that firing the motor fired for 41.2 seconds and produced 17,172 lbs of thrust. Fourteen months later it went on to successfully power the RV-A-10 rocket from Cape Canaveral. The Hermes is credited with validating the concept of large solid fuel motors. There is also a series of photos that show the process of prepping and loading the shuttle SRM's that I'll post later.

Wednesday, May 30, 2012

TR-1 Motor

I haven't had a chance to do much work on the TR-1 motor...I'm satisfied with the design and am ready to start machining. I just need to finish machining the hardware that I mentioned in my previous post.

I modeled the nozzle in 3D. I find that this helps with the machining if I can move the part around and think how best to machine it.

The design is similar to the MiniSShot nozzles that I machined in that it consists of two main pieces. There were a number of reasons that we chose to construct the MiniSShot nozzle in two sections, but for the TR-1 motor the decision was made simply to ease fabrication. Constructing the nozzle from two pieces allows me to use some stock that I had on hand and more importantly significantly reduces the amount of material that I'll need to remove. I have a piece of 1018 for the shoulder portion of the nozzle and some 12L14 for the convergent/divergent piece.

I modeled the nozzle in 3D. I find that this helps with the machining if I can move the part around and think how best to machine it.

The design is similar to the MiniSShot nozzles that I machined in that it consists of two main pieces. There were a number of reasons that we chose to construct the MiniSShot nozzle in two sections, but for the TR-1 motor the decision was made simply to ease fabrication. Constructing the nozzle from two pieces allows me to use some stock that I had on hand and more importantly significantly reduces the amount of material that I'll need to remove. I have a piece of 1018 for the shoulder portion of the nozzle and some 12L14 for the convergent/divergent piece.

Thursday, May 17, 2012

TR-1 Rocket Motor initial CAD

Wednesday, May 16, 2012

TR-1 Rocket

With my sons first visit to the desert to view a rocket launch and to help out with the static test of the Sugar Shot to Space's latest motor a few weeks behind us, we've decided to build a rocket. The last new motor that I designed, built and flew was this one:

That was about two years ago and Theo doesn't remember it at all. That was a new motor that used an existing aero shell that had to be extended a bit to fit the new motor. The whole process of designing and building a rocket is fun for me and actually getting out and flying it is the icing on the cake. Since Theo loves tinkering out in the garage as much as I do, we're going to design and build this from scratch. We don't plan on re purposing any existing pieces, other than maybe some of the electronics. While it may take a little more time with Theo's "help". Did I ever tell you about the time I thought he was cleaning up on the other side of the garage but was actually bungee cording my motorcycles together. Despite any setbacks we may encounter, I'm really looking forward to going through the whole process with him. I'll try and document the entire process here.

Theo's requirements are that the rocket be big and orange...maybe with some blue. With that in mind the motor is going to be based on this N-class motor that I designed, built, and tested a while back. You can see that motor by going here. The biggest difference is that the TR-1 motor will utilize EMT for the motor casing. As you may or may not know, EMT is one of my favorite motor casing materials. I'm not sure why, I think it's because of other peoples attitudes towards it. I discussed my feelings about EMT, or steel in general during the development of my last motor (the one pictured above), you can read that by clicking here if you're interested. The biggest advantage that I'll get from EMT for this motor is that I can use a standard four inch mailing tube for a casting tube. Four inch EMT actually has an OD of 4.5" and with a wall thickness of 0.083" the ID should be around 4.334". That should allow for a few wraps of rosin paper to be used as an insulator, like I did in the my other design. Though with EMT this isn't necessary for the casing, but will help cut down on the heat transferred to the aeroshell. My initial 4inch motor had and ID of four inches and I was rolling the casting tubes by hand, very time consuming and messy. Using Richard Nakka's "casing" spreadsheet I found that 4 inch EMT has a burst pressure of 2573psi. With a design pressure of 1050 PSI I end up with a design safety factor of 1.7 and a burst safety factor of 2.45, pretty conservative.

I did an initial SRM design, summarized here:

While my previous N-class motor was on the edge of the M/N class this new design ends up solidly in the middle of the N-class and should provide for an awesome experience.

More to come...

Sunday, July 18, 2010

Launch Day

I had a lot of fun at the launch. The new motor performed really well . The flight went well and the chute was deployed at apogee. Unfortunately the parachute separated from the rocket and it came in ballistic. The good news is that most of the motor survived and may give some clue as to what caused the recovery failure...more on that later. I don't think many of the AIAA members had ever seen a "sugar" motor before and I think a lot of them were surprised and impressed.

Many of the competing teams seemed to have a tough time of it with several launch pad mishaps and a few in flight failures. By the afternoon though there had been some nicely executed flights. Overall it was a good day and it was pretty cool to see so many people participating. There are a handful of other photos here.

Tuesday, July 13, 2010

Launch update

Change of plans. Once I started looking into what actually had to be done to prep the camera rocket for this weekends launch, I realized that there was actually more to do than I had anticipated. Coupled with the fact that I'm not going to be able to go out early to cast the the propellant for that larger motor it became apparent that I needed a plan B. I quickly decided that I could modify an older/retired aeroshell to fit the 2.375" motor that I have been working on. The initial static test of that motor ended abruptly, but I modified the design and it's been ready to be re-tested for some time now. Finding the time has been the issue so plan B seems like the way to go; I get to fly something and test the motor. I still need to document the changes to the 2.375" motor, but basically three things changed: I went back to a propellant formulation that I know well (60/40 KNSB), I redesigned the core to be stepped to help address any erosive burning issues, and I'm using a smaller igniter. I chose the 60/40 ratio to help reduce the chamber pressure as KNSB has a higher burn rate then the KNERSB formulation that the original motor test used. At least in theory. While the ambient burn rate that I measured fell in between KNSB and KNER, I'm not convinced that the burn rate at operating pressure behaved the same way. The initial testing of the KNERSB propellant didn't seem to exhibit some of the same characteristics of KNER propellant, namely difficulty with ignition or slow start up. The failure mode was over pressurization which resulted in the forward bulkhead being blown out. I felt that the last test had too many new things going on: new propellant formula, High L/d. Having made changes to address both, I feel confident enough to try a flight test. Hey, that's why they call it experimental rocketry!

Anyway, I chopped the black and orange rocket into pieces. Once I get the pieces put back together it should look basically the same from the outside. It's kind of exciting refurbishing an old rocket that probably last flew in 2002-2003. The largest motor that boosted this aeroshell was a K-class motor and the 2.375" motor is an L-class motor, so it's a bit of a step up in thrust. Parachute deployment will be handled with a timer. I'm leaving out the more expensive altimeter because of the untested nature of the motor, but I am going to include a video camera because you want video even if things go wrong. Pictures of the new rocket to come soon.

Sunday, December 20, 2009

"Test Complete"

One of the very first large solid rocket motor static tests that I witnessed was out at the RRS nearly ten years ago. That motor was huge, 12 inch diameter if I remember correctly. A couple of seconds into an 8 or so second planned burn the casing failed... spectacularly! The first thing I heard was Dave Crisalli on the PA system calmly declare "test complete!" I was hooked, this amateur rocket thing was for me.

One of the very first large solid rocket motor static tests that I witnessed was out at the RRS nearly ten years ago. That motor was huge, 12 inch diameter if I remember correctly. A couple of seconds into an 8 or so second planned burn the casing failed... spectacularly! The first thing I heard was Dave Crisalli on the PA system calmly declare "test complete!" I was hooked, this amateur rocket thing was for me.Ok, so yesterdays failure was not nearly as spectacular, but a fraction of a second after ignition I heard Dave's voice in my head declare "Test Complete". I have a couple of theories on what went wrong and a ton of video that I will post. The likely cause of the failure was probably a combination of things, but I think the leading cause was not the motor design, but how we retained it to the "test stand" and the pressure port....more on that later.

In the first image you can see the motor is up to pressure. In the second image (separated from the first by 1/30th of a second) the bulkhead has been blown out of the casing. The third image shows one of the two camera's close to the motor and the pressure gauge in the lower right hand corner on their way out. The fourth image shows the casing and nozzle "landing" after a full ten seconds in the air.

I'll need to make a new casing and bulkhead, and with a few small adjustments to the design I should be ready to test again soon. There were a couple of interesting observations concerning the alloyed sugar propellant that I'll post once I get the videos in order. Overall, I think the KN/ER/SB has advantages over KNER or KNSB and I'm going to continue down this path for a while.

Sunday, October 25, 2009

2.375" Motor Updated

I changed the design again. I decided to optimize the it for KNER propellant by adding two additional segments. The additional propellant brings the motor up to a solid L-class motor and the chamber pressure sims. at right about 1000psi. I'm hoping to have an opportunity to test fire it for the first time in early December

I changed the design again. I decided to optimize the it for KNER propellant by adding two additional segments. The additional propellant brings the motor up to a solid L-class motor and the chamber pressure sims. at right about 1000psi. I'm hoping to have an opportunity to test fire it for the first time in early December

Update: I updated the SRM output to correct a mistake. I had been using the wrong grain OD.

Saturday, January 19, 2008

Old Launch Photos and Stuff

Going through some old photos and rocket related things recently, I came across some photos from 2002. At that time two of the largest motors that I had were designed around two inch diameter "washing machine standpipe" that I found at Home Depot. I decided to try these pipes at the time because they seemed to be very good quality, good/consistent weld, and dimensionally consistent. They also have a thin (0.035") wall thickness which makes for a very lightweight casing. I designed two motors that utilized this casing material. Both motors used identical casings, bulkheads, and closures, but one was designed to use a single unrestricted grain and the other a single restricted grain. The differences in the nozzles are shown in the drawing above. I was concerned about the low initial thrust of the motor that used the single restricted grain and tried to reduce the weight of the nozzle for that motor as much as possible. In the end both motors ended up weighing nearly the same (1.75 lbs). I static tested the unrestricted motor and the numbers correlated closely to the design. Ultimately both motors flew numerous times at the RRS. They were simple to prepare on site (due in part to the fact that each needed only a single grain and that the motor was used as the casting mould). The motors proved to be durable, consistent, and fun to fly.

In the first photo you can see the casing with its nice shiny zinc coating. It is not that shiny from Home Depot, but the finish didn't take much time. Unfortunately the zinc blistered after the initial firing, so the coating was removed with a quick dip in muriatic acid. The 5th photo shows Peter and I taking the rocket out to the launch tower. The 6th photo shows (from left to right) Greg Coleman, myself, Kevin Koch, and Alan Hoyt lifting the launch tower into position. The 7th photo is Kevin, myself, and Alan. The orange and black aeroshell flew a total of five times at the RRS on three different motors. I made it from three inch diameter heavy walled cardboard tube that Kevin found in a dumpster. The fins were cut from quarter inch plywood and were epoxied on to the tube and reinforced with a layer of heavy fiberglass. The nose cone was turned from a block of pine. Eventually, it became too small for the new motors that I was making and was retired. It was always difficult to adjust the tower for it correctly since it had three fins and the tower at the RRS is built for a four fin rocket.

Photos 6-10 were all taken by Tony Richards.

Monday, October 8, 2007

New Motor

Saturday, May 26, 2007

Four Inch Diameter SRM

This is a four inch diameter motor that I've been working on for a while now. This motor is very similar to the motor that I flew last month. Both motors used 6061-t6 aluminum for the casing and 12L14 steel for the nozzle. The grain geometry was also very similar, with the major difference being that this motor uses six segment instead of four. This motor has been fired twice now. Both firings occurred at the RRS's Mojave Test Area. I normally go out to the site the night before to do propellant/motor prep, then sleep in a tent on site that night. The first firing experienced a burn through in the casing. The motor fired well for most of the burn and damage was limited to the casing, so I was very pleased with the initial firing. I made several small changes to the design; first was reducing the diameter of the casting tubes/inhibitor slightly to accommodate an increase in the casting tube/inhibitor thickness of 15% , lastly the casing insulation thickness was increased by 25%. I consider the second firing to be successful. The ignition was a bit slow, due to much of the igniter material being expelled from the nozzle. The use of a pyrogen canister should solve this problem. I am pleased with the resulting ISP of 127 (ISP being a measure of propellant performance). The important thing for me was that the casing temperature didn't begin to rise until several seconds after the test indicating that the insulation was effective. Post test inspection revealed that the insulation had been breached in several places, but the video and temperature data do seem to support the idea that these breaches occurred post firing. I may still add a bit more insulation for added safety though.

Labels:

motor design,

n-class,

rocket motor,

Sorbitol,

srm,

static test

Wednesday, May 9, 2007

Motor Stats

I thought I'd post some quick stats on the motor that I flew on the 28th of April. The motor was designed to produce approximately 425 lbs of thrust for 2.2 seconds for a total impulse of nearly 950 lbs. The motor (nozzle, casing, bulkhead, snap rings, inhibitor, and casing liner) weighted in at 5.96 lbs. The propellant grain, consisting of 4 segments in a bates grain configuration, weighted in at 7.31 lbs, with a port/throat ratio of 1.5625. The propellant was mixed in a ratio of 65/17.5/17.5 (KnO3/Sorbitol/Sucrose) and cast into 3" mailing tubes that have an ID of 3" and an OD of 3.125". The casing insulation consisted of four layers of rosin paper, purchased at Home Depot. The casing and bulkhead are fabricated of 6061-t6 aluminum. Using Richard Nakka's casing.xls the design safety factor was determined to be 2.2 with a burst saftey factor of 2.94. The nozzle is fabricated from 12L14 "leaded steel" and had a throat diameter of 0.64" and an expansion ratio of 12. There was no measurable throat erosion post firing and the nozzle appears to ready for another firing. When I took the motor apart post flight the insulation was nearly intact, having been breached near the bulkhead. The casing appears to be fine and there is no measurable deformation.

Labels:

motor design,

rocket motor,

Sorbitol,

static test

Monday, May 7, 2007

Launch video from May 20, 2006

Here is some of the video taken of the first time this yellow rocket was flown. In it's first flight it was flown with a smaller motor, no camera payload, and not boat tail. If you look closely at the video, you can see the shadow cast by the exhaust trail shooting out across the desert behind the launch tower. I also included a photo of both motors that I've flown in this rocket so far. The smaller motor uses steel EMT for the casing. The larger motor uses an aluminum casing and snap ring closures.

Subscribe to:

Posts (Atom)