The 2.375" rocket motor is ready to test but I haven't had the opportunity to get out the test site. I have been feeling the urge to be doing some rocketry though and with that in mind I decided to build something. I chose something small. While the SStS project was immensely satisfying and a great educational experience it did lack a big part of what I enjoyed from my early days in rocketry. The thing i really miss is taking something from concept all the way through to completion, being involved with every step, and then actually getting out to the desert and launching the vehicle. It turns out that I had a rocket that I had promised to rebuild after it was lost over 8 years ago. That rocket was powered but Richard Nakka's C-400 motor, slightly modified to utilize KNSB, a Sorbitol based propellant versus Sucrose which the C-400 was originally intended to be fueled with. I came across this VCP design printout a while back. At the time it wasn't the largest rocket I had built or flown but it was definitely the highest performance one with a lot of attention to drag, weight, and construction details.

Here's a photo of its only launch. My brief blog entry of the launch can be found by clicking

here.

As you can see by the photo, my daughters paint scheme won out over my own preference. I hope to document this build to a much greater extent than the first time around. With that in mind here are my initial design thoughts. The hope is to create a motor/rocket that is simple to construct, durable, and easy to prep for launch. I'm initially designing towards a Dextrose based propellant but am hoping to be able to use several of the other sugars available. Actually my notes indicate that the above launch used a propellant that was comprised of 50% Sucrose and 50% Sorbitol.

Casing design:

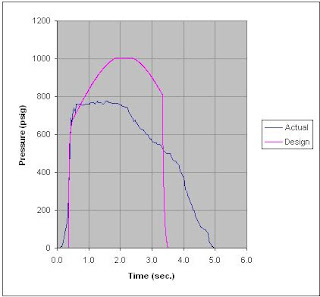

SRM output:

Here is my initial CAD: