I fired two motors this past Saturday. One was an AP based motor and the other was a KNO3 based motor. Both motors were of approximately the same total impulse, but it wasn't really a fair comparison. The KNO3 motor used Xylitol for the fuel. I first heard about this sugar on Scott Fintels web site, and it was available at the local Whole Foods store. It has a low melting point and casts very nicely, the problem was that the grains took a long time to cure, weeks in fact. Anyhow, the propellant in the AP motor is fully characterized and the propellant in the KNO3 motor not so much. The side by side comparison is still interesting to watch though.

Monday, November 19, 2007

Sunday, November 18, 2007

Composite motor class

I took part in a composite motor class this past weekend. The class was taught by Dave Reese and was conducted at the Friends of Amateur Rocketry site. The class was a lot of fun and full of lots of useful information. Dave is currently a student a USC and I'm sure that he is very busy but despite this he did a great job organizing and conducing the class. The motor that we prepped propellant for was based on standard high powered rocketry hardware of which I have none, so I made some hardware based on drawings that I found on the Loki Research website. The hardware worked really well; I like the simplicity of the Loki design. Here is a video of the class motor that I static tested, I didn't have any instrumentation partly because I didn't want to risk any equipment on untested hardware and a propellant that I don't have much experience with, but mostly because I've been so busy lately that I just didn't have time to get anything together in time. The design/propellant is pretty well characterized though. The thrust produced should have been in the neighborhood of 90lbs with and Isp of around 185-190.

The Paul Breeds of Unreasonable Rocket were also at the site. Paul senior was flying an RC helicopter loaded with telemetry to gain information for their Lunar Lander Challenge quest.

The Paul Breeds of Unreasonable Rocket were also at the site. Paul senior was flying an RC helicopter loaded with telemetry to gain information for their Lunar Lander Challenge quest.

Saturday, November 3, 2007

Composite Propellant Class

Later this month I'll be participating in a composite propellant class at the FAR site. The class is being taught by Dave Reese. Dave's a student at USC and was involved with this awesome project flown at the RRS some time ago. Photo by James Davidson.

Here is a picture of some of the 38mm hardware that I made myself for the class. I only had to buy the tubing. I bought enough for three casings for under $30. I had enough "scrap" pieces laying around for the bulkheads and nozzles.

Here is a picture of some of the 38mm hardware that I made myself for the class. I only had to buy the tubing. I bought enough for three casings for under $30. I had enough "scrap" pieces laying around for the bulkheads and nozzles.

Thursday, October 25, 2007

Nozzle From Recent Static Test

After cleaning up the motor after last weekends static test I noticed distinctly copper coloration to the nozzle. I have noticed this to a lesser degree in the past few static tests that I've conducted. I attributed it to the copper tubing that I have been using for the pressure gauge. It didn't really make sense because that tubing is upstream of the exhaust flow so it seems like any copper from the plumbing would be pushed towards the gauge, not the nozzle. There are two significant differences between this test and the others. The first is that in this firing the nozzle appeared to get much hotter than the other nozzles that I have noticed this copper coloration in, the other is that in this nozzle there appears to be little globules of copper colored material that have been driven out of the surface of the of the nozzle. the thing that I can't figure out is that these nozzles are made of 12L14 steel, which is made up of Iron, Carbon, Manganese, Phosphorus, Sulfur, and Lead. So where does the copper coloration come from?

Monday, October 22, 2007

Static Test

This past Saturday I participated in a sugar propellant class at the Friends of Amateur Rocketry (FAR) facility. Brent Dougherty did a nice job presenting a general overview of how to safely work with and cast sugar based propellants. Thanks to the FAR guys Kevin, Mark, Ted and the others for letting us use the site. They have done an amazing amount of work on the site, including a massive vertical test stand (I don't remember what it's rated for).

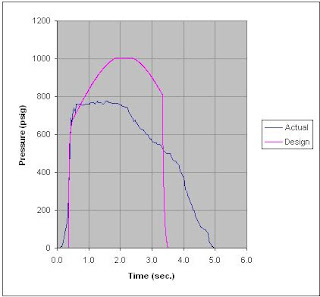

As part of the class I fired an L-class KNO3/Sorbitol demonstration motor. The firing went well and good data was collected. This is a simplified set-up from what I've used in the past and it worked well. I'm planning on making some adjustable steel brackets that mount with bolts rather than the cargo straps. Here is the set-up:

In the picture taken just after the firing you can see the nozzle glowing red hot, once I got the motor torn apart and cleaned, everything appeared to have survived the firing just fine. The gauge measuring thrust began to register data about a tenth of a second or so before chamber pressure began to be recorded. I suspect that the pressure port was briefly clogged by the igniter initially. After tearing the motor apart I found a glob of melted plastic that used to be the soda straw that held the BP.

In the picture taken just after the firing you can see the nozzle glowing red hot, once I got the motor torn apart and cleaned, everything appeared to have survived the firing just fine. The gauge measuring thrust began to register data about a tenth of a second or so before chamber pressure began to be recorded. I suspect that the pressure port was briefly clogged by the igniter initially. After tearing the motor apart I found a glob of melted plastic that used to be the soda straw that held the BP.

As part of the class I fired an L-class KNO3/Sorbitol demonstration motor. The firing went well and good data was collected. This is a simplified set-up from what I've used in the past and it worked well. I'm planning on making some adjustable steel brackets that mount with bolts rather than the cargo straps. Here is the set-up:

In the picture taken just after the firing you can see the nozzle glowing red hot, once I got the motor torn apart and cleaned, everything appeared to have survived the firing just fine. The gauge measuring thrust began to register data about a tenth of a second or so before chamber pressure began to be recorded. I suspect that the pressure port was briefly clogged by the igniter initially. After tearing the motor apart I found a glob of melted plastic that used to be the soda straw that held the BP.

In the picture taken just after the firing you can see the nozzle glowing red hot, once I got the motor torn apart and cleaned, everything appeared to have survived the firing just fine. The gauge measuring thrust began to register data about a tenth of a second or so before chamber pressure began to be recorded. I suspect that the pressure port was briefly clogged by the igniter initially. After tearing the motor apart I found a glob of melted plastic that used to be the soda straw that held the BP.

Labels:

motor test,

rocket motor,

Sorbitol,

srm,

static test

Saturday, October 13, 2007

Terrapin Nozzle

One of my all time favorite small sounding rockets has to be the Terrapin. Click here to see my earlier Terrapin post including pics and launch footage. Developed at the University of Maryland in the Mid '50s, it is a study in simplicity. It was a two stage vehicle that used existing motors, fins welded directly to the motor case, a zero length launcher, and had tremendous performance. One of the cooler pieces of Terrapin hardware has to be the nozzle from the booster. The booster was a modified Deacon motor. Here is a photo of another one of my favorite small rockets that used two Deacon motors for the initial boost. I have been doing some 3D modeling recently so I did a model of the Terrapin nozzle. I found a drawing of the Terrapin in Small Sounding Rockets which is a great book with a lot of drawings and photos. I wish the illustration quality was a little better, but I highly recommend it to any one interested in rockets/rocketry. The Terrapin nozzle appears to have been of all steel construction. It also appears to have had an O-ring seal between the nozzle and the casing liner and another between the nozzle and the casing. Retention appears to have been through a number of small roll pins (not shown in renders) I would love to see what one of these nozzles looked like after firing. Any additional info., photos, or corrections are welcome.

Anyway, here are the renders:

Anyway, here are the renders:

Thursday, October 11, 2007

Nozzle Cross Section

Here is a render of the new nozzle for the camera rocket. This render shows the much shorter that usual convergence section, this was done in an effort to reduce overall weight while still keeping the rest of the nozzle fairly "beefy".

Monday, October 8, 2007

New Motor

Thursday, October 4, 2007

Camera Rocket, v02

I've been thinking about the next flight of the camera rocket. It didn't take me long to come to the conclusion that I wanted to do some thing different, either a larger motor or a different camera orientation. Initially I gave more thought to the camera, because there really wasn't much room left in the aeroshell for a larger motor. Then one weekend while I was out in the garage I came across the motor casing from the first firing of my N-class motor. That firing suffered a breech in the insulation and a burn thought near the bulkhead. I added more insulation and at the next test had a successful firing. While this motor is much too long for this aeroshell, it turns out that diameter would fit if I removed a tiny amount of material from the heads of the retaining screws. I played around with the numbers for a while and decided that I could use the bulkhead, nozzle, and a shorter section of the casing in a workable 3 grain configuration. I was planning on using the same nozzle as the larger 6 grain motor, which would have resulted in a very low Kn or grain surface area/throat area. My plan was to increase the burn rate by adding a catalyst (iron oxide). I wouldn't have gotten the chamber pressure up to the initial design of 1000 psi, but I figured that I would be able to get it up to around 600 psi. While performance would suffer some, the overall performance should have been fine. It didn't take me long to decide on fabricating a new nozzle though. The deciding factor was weight though, not performance. The new motor would already weigh more because of the increased propellant load, so using the existing nozzle which is fairly heavy wasn't seeming like such great idea any more. The rocket has flown very well in both of it's previous flights but adding a lot of additional weight to the tail end didn't seem like a good idea. I decided to fabricate a new nozzle, well essentially a new motor. I decided to stick with the 7:1 expansion ratio to reduce the weight of the nozzle and simplify the machining. You can see a comparison between the new motor design and the previous motor that powered this rocket.

While they appear to be very similar in size the new motor should provide a 33% increase in total impulse. Once the nozzle was fabricated, I was pleased to find out that it actually weighs less than the nozzle from the 3.5" motor. Unfortunately, the shorter nozzle also means that the boat tail is going to be shorter, but I am considering extending it beyond the nozzle exit a bit. The previous flight got to 14,400' and I'm hoping this flight can get close to 18,000'. I am planning on adding another on board camera, or adding a mirror to the existing camera bay to shoot straight down. Maybe I'll do both.

Here are the basic designs of the new motor and the previous motor.

The new nozzle design.

I did a 3D model of the nozzle. This is the first time that I've done this and it was very helpful to be able to rotate around the piece before starting to actually cut metal.

Here is the finished nozzle. It looks just like the 3D model.

While they appear to be very similar in size the new motor should provide a 33% increase in total impulse. Once the nozzle was fabricated, I was pleased to find out that it actually weighs less than the nozzle from the 3.5" motor. Unfortunately, the shorter nozzle also means that the boat tail is going to be shorter, but I am considering extending it beyond the nozzle exit a bit. The previous flight got to 14,400' and I'm hoping this flight can get close to 18,000'. I am planning on adding another on board camera, or adding a mirror to the existing camera bay to shoot straight down. Maybe I'll do both.

Here are the basic designs of the new motor and the previous motor.

The new nozzle design.

I did a 3D model of the nozzle. This is the first time that I've done this and it was very helpful to be able to rotate around the piece before starting to actually cut metal.

Here is the finished nozzle. It looks just like the 3D model.

This illustrates the basic layout of the motor in the camera rocket (well minus the camera). When I finish the boat tail and decide exactly how I'm going to lay out the cameras for the next flight, I'll do a new illustration.

Wednesday, September 19, 2007

Early Dual Burn Motor Test

This is a video of a static test that I conducted back in 2005 when I first got involved with the Sugar Shot project. The dual burn concept is not new, but I haven't heard of any amateurs pursuing it. At this size, I don't think you'd realize much benefit. However, in a slightly larger motor, such as the one that we are currently constructing, you begin to see some real benefits. The concept is similar to staging, but in some ways simpler to execute. One of the major difficulties is that the first half of the casing and the nozzle are subjected to twice the heating that they would have to endure in a two stage design. The motor that we are currently working on has the potential to reach nearly 50,000 feet, which is considerably higher than you would expect to go with a "standard" motor that expends all of it propellant close to the ground in denser air. Despite some minor problems, I considered this early test to be successful. The o-ring on the upper bulkhead was damaged, and I didn't have a replacement. That resulted in a small leak during the 2nd burn. However, there were several key things that did seem to work. Most notably:

The first propellant grain burned properly and ignited the epoxy plug .

The first propellant grain burned properly and ignited the epoxy plug .

The epoxy plug burned through without igniting the second propellant grain.

The burnt remains of the epoxy plug did not obstruct the nozzle.

The mid-bulkhead did not seem to have a significant effect on the 2nd phase thrust.

The burnt remains of the epoxy plug did not obstruct the nozzle.

The mid-bulkhead did not seem to have a significant effect on the 2nd phase thrust.

Labels:

dual phase,

motor test,

rocket firing,

rocket motor,

SStS,

static test

Saturday, September 15, 2007

Norton's Surplus

It's been really busy at work lately; long hours, skipped lunches, etc. I skipped lunch again yesterday, but instead of working through lunch James and I drove over to Norton's Surplus in North Hollywood to look around. Nothing has changed much since the last time I was there. The outside area had been cleaned up quite a bit though, which allowed me to get a picture of a large cylindrical motor that was nearly buried under debris last time. Four or five years ago on my first visit there I noticed a 318mm rocket motor with its nozzle pointed up in the air. It had a bunch of hoses piled in front of it. I was able to climb on top of the pile and snap a few close-up pictures. I'm not sure what it's from, but a quick Google search turned up this photo of a Little John rocket on display at the Smithsonian Air and Space museum that looks very similar. I got the photo from this blog. I took a photo of the inside of the casing . In that photo you can see four "rods" that run the length of the casing. I'm not sure what they were for, maybe they supported the propellant grain or maybe they are resonance rods like those pictured in this diagram of what I believe is a Nike Ajax motor. The nozzle appears to be all steel construction with no throat insert. The entire nozzle is badly rusted, but the throat doesn't seem to have suffered any asymmetrical erosion.

Wednesday, September 12, 2007

Static Firing Video

I plan to start posting some videos form the past. I'll post them as I find the time, many of them were shot on an analog camcorder and need to be converted to digital. This one is a close up view of the nozzle during the second firing of the ballistic evaluation motor for the Sugar Shot to Space effort. It really illustrate well the amount of heat generated. It was a disappointing test in that the casing failed and we had problems with the data acquisition. You can find the complete report here. It did provide some useful data though and I managed to get some good video.

Friday, September 7, 2007

Minisshot Motor Progress

I started threading the motor components. I've only done the six holes that connect nozzle shell to the nozzle ring, so I have a long way to go. It's exciting that those 12 holes line up so well, though. The nozzle design consists of two main pieces. The purpose is to reduce the amount of heat transfer from the throat region to the composite motor casing. The two pieces are separated by a extremely high temp. gasket. In addition to that, the shell flange has a slightly smaller diameter than the ring so that there is no direct metal to metal contact between the two pieces.

Monday, September 3, 2007

MiniSShot Motor Update

I just completed the mid-bulkhead, pictured in the middle above. That's the last of the major components for the Minisshot motor. There is still a lot to do, not the least of which is to tap the 102 screw holes. It feels good to have the major metal cutting completed though. The next major milestone in my mind is putting all the components together for the first time and seeing how it all fits together. I wonder what the motor assembly time is going to be with all those screws?

Tuesday, August 28, 2007

Updated Profile

Thursday, July 26, 2007

Forgotten Launch Footage

A few weekends ago I was going through some camera stuff and realized that I had some video from my last launch on April 28th that I had forgotten about. Actually, I hadn't forgotten about it but after viewing it immediately after the launch I realized that it was badly out of focus and decided that it wasn't all that interesting. The footage that I got from the on board camera was much more interesting. Seeing it again after three months though, it seems more interesting despite the poor video quality. The camera was placed at the base of the launch tower pointed along the tower axis. The resulting footage is fun to watch because it really gives a sense of how fast the rocket left the ground. I will probably try and capture this view again next time.

Sunday, July 1, 2007

Nice Static Firing in Iceland

Congratulations to Magnus and friends. I saw that Magnus Mar Gudnason recently had a successful static test of his new design. Magnus and his friends have done some really nice work and I'm happy to see that he got a good test with this new motor. He has posted a lot of info on the Amateur Icelandic Rocketry forum, including drawings, photos of the assembly process, video, and results. Definitely worth checking out. I especially like that he is using a steel nozzle for this motor, for no good reason other than it looks cool. It seems like a lot of people opt for graphite when they get to larger sugar motors, I guess for the ease of machining. It should be an awesome flight when he's ready to fly it.

Saturday, June 30, 2007

Minisshot Nozzle Update

The nozzle ring is nearly completed. The 24 ring to casing screw holes and the 6 shell to ring holes all still need to be tapped. I'll probably have that task completed before the weekend is over. Indexing and drilling the 24 retention screw holes was more time consuming than I was expecting. The Mid-bulkhead design has 48 screw hole locations, so that will be even more challenging in that regard. I was worried about the alignment between the shell and the ring. It looks good though, the holes line up very well. I'm also pleased that it came in right at the predicted weight of 365 grams. Just for fun I looked at McMaster-Carr to see what six titanium machine screws for the shell to ring connection would cost; over forty dollars after shipping. Too expensive! The shortest ones that they had were a bit too long anyway. I may try and stop by Luky's Surplus Aviation Hardware in Burbank next week and see if I can find some there. Their prices and selection are awesome, finding the exact one that I want will be the hard part. I don't think that it's absolutely necessary, but those six screws will be exposed to significantly more heat than the ring to casing screws.

Wednesday, June 27, 2007

Farside Launch

Here is another Universal newsreel video. This one is of a rocket launched as part of Project Farside conducted by the US Air Force in the late 50s. The first stage consisted of four Thiokol Recruit rockets, the second stage used a single Recruit, the third stage used four Grand Central Arrow II motors, and the fourth stage was a single Arrow II. The rocket was carried aloft by a large balloon and fired from an altitude of 19 miles. The system had a potential altitude was 4000 miles (6400 km). I didn't find much info about the rocket online, and what I did (including the photo above) came from here. The video features the balloon launch from the ground and shows the rocket firing through the balloon. The audio quality is a little poor and the the background music seems like a very odd choice.

Tuesday, June 19, 2007

Terrapin Rocket Launch

I recently came across a great Universal Newsreel from 1956, showing the launch of a Terrapin sounding rocket from Wallops Island, Virginia. The site where I found it on is http://www.archive.org/ . There are a number of other interesting Universal News Reels there featuring various rockets The newsreels often times seem to have a number of subjects on each reel, some of which are not all that interesting. The newsreels are appartently old enough to fall into public domain though so I edited out the uninteresting part of the Terrapin newsreel.

Saturday, June 16, 2007

New Nozzle

I recently began working on a new nozzle for the Sugar Shot project. You can read more about the project here. This nozzle is intended to be used for the MiniSShot motor. This Motor is a very ambitious design being a two phase motor like our earlier BEM design and because, for the first time, we will be using a composite motor casing. The nozzle for this motor is designed to isolate the composite casing from the hot nozzle as much as possible and as such the nozzle has been designed to consist of five separate components. The nozzle consists of a nozzle ring, nozzle shell, graphite insert, heat resistant gasket, and a cast in place ablative on the inlet side. I recently completed the nozzle shell which is one of the more complex pieces that I have fabricated. I am pretty pleased with the result and plan to move onto the nozzle ring next.

Saturday, June 2, 2007

Interesting Rocket Photos

I recently saw some cool old photos on Dick Staffords rocket Blog, but want to add one more. I came across this photo some time ago and always thought it was really cool. It looks very similar to some of the vehicles that Dick posted photos of, probably from the same place (Wallops or White Sands) and time. I'd also like to thank Dick for mentioning my site and mention that his site is great. Nothing even remotely related to rocketry seems to get by Dick.

Thursday, May 31, 2007

Amateur Icelandic Rocketry

There is some nice amateur rocketry going on in Iceland. Magnus and Smari have built and flown some very nice hardware. You can see their stuff here. They recently fired a very nice looking 100mm motor that looks very similar to my 4 inch design. It looks like the nozzle got some damage, but I think it looks like it might be salvageable. Looking forward to seeing that video. Magnus has also recently started a rocketry forum.

Saturday, May 26, 2007

Four Inch Diameter SRM

This is a four inch diameter motor that I've been working on for a while now. This motor is very similar to the motor that I flew last month. Both motors used 6061-t6 aluminum for the casing and 12L14 steel for the nozzle. The grain geometry was also very similar, with the major difference being that this motor uses six segment instead of four. This motor has been fired twice now. Both firings occurred at the RRS's Mojave Test Area. I normally go out to the site the night before to do propellant/motor prep, then sleep in a tent on site that night. The first firing experienced a burn through in the casing. The motor fired well for most of the burn and damage was limited to the casing, so I was very pleased with the initial firing. I made several small changes to the design; first was reducing the diameter of the casting tubes/inhibitor slightly to accommodate an increase in the casting tube/inhibitor thickness of 15% , lastly the casing insulation thickness was increased by 25%. I consider the second firing to be successful. The ignition was a bit slow, due to much of the igniter material being expelled from the nozzle. The use of a pyrogen canister should solve this problem. I am pleased with the resulting ISP of 127 (ISP being a measure of propellant performance). The important thing for me was that the casing temperature didn't begin to rise until several seconds after the test indicating that the insulation was effective. Post test inspection revealed that the insulation had been breached in several places, but the video and temperature data do seem to support the idea that these breaches occurred post firing. I may still add a bit more insulation for added safety though.

Labels:

motor design,

n-class,

rocket motor,

Sorbitol,

srm,

static test

Monday, May 21, 2007

Unusual Rockets

I regularly search on eBay for unusual rocket hardware. I found this intriguing auction a while back. I didn't turn up much info about this particular small sounding rocket. A quick Google search did turn up this info though...

"Another approach has been developed by Texaco Experiment Incorporated. Their rocket, named Cricket, uses a cold propellant to boost the rocket to an altitude of 3,000 feet. At peak altitude a parachute is deployed which allows the whole unit to descend intact. The propellant is acetone and dissolved CO 2. A 0.5-pound payload can be carried and the rocket is reusable at least 10 times. The launch system is simple and can be safely operated by untrained personnel. With additional altitude and payload capabilities, this system might well be adapted to the problem at hand."

NASA TECHNICAL NOTE

D-1277

STUDIES IN FAR-FIELD ACOUSTIE_PROPAGATION

NASA TECHNICAL NOTE

D-1277

STUDIES IN FAR-FIELD ACOUSTIE_PROPAGATION

Subscribe to:

Posts (Atom)