I've got the SStS TM-1 motor case nearly finished. The screw hole locations are all indexed and the ends trued up so all that is left is to drill them out and a little polishing.

Friday, May 31, 2013

Wednesday, May 29, 2013

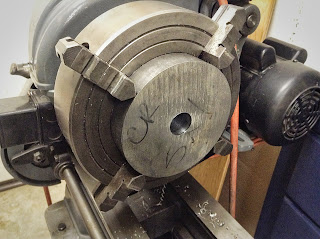

SStS TM-3 MOTOR CASING

I started on the TM-3 motor tube this morning. It absolutely dwarfs my lathe, but being aluminum instead of steel it's much easier to work with than the previous DSS motor cases that I've worked on. I only need to index the retaining screw locations and true the ends. I should be able to finish this tonight, then I'll get to work on the other half of the TR-1 nozzle. With approximately 90 lbs of propellant this motor should produce a total impulse that fits it into a P-Class designation.

Sunday, May 26, 2013

TR-1 ROCKET UPDATE

I finished all of the lathe operations for the nozzle ring. When I took it off the lathe I was struck by how heavy it was. It doesn't really matter for a static test, but I decided to go back in and remove a bit of the excess material. The amount of material that was removed (drawing above) reduced the parts weight by nearly 30%. It will also make it easier to drill and tap the twelve screw hole locations as they are no longer blind holes. There are still a few areas I can pare down but I'll hold off for now.

I'm going to take a quick break from the TR-1 motor and work on the SStS TM-3 motor casing which seems to be coming together quite quickly. This is a pretty large O or P-class motor which is about as big a "Sugar" motor as I've ever heard of. It shouldn't take me long to finish work on the casing and then I'll get back to work on the TR-1 motor.

Labels:

casting,

DSS TM-3,

machining,

SStS,

TR-1 Rocket

Friday, May 24, 2013

TR-1 MOTOR UPDATE

Wednesday, May 22, 2013

TR-1 MOTOR UPDATE

GROVER AEROSPACE

I went though my links to see what other people were doing. Some are less active than they use to be, some more. I got rid of a couple of links and I also found some new sites. One that I found to be particularly interesting is James Grover's site. I hadn't read very far before I found this sentence that he had written in the response to a question. "I don't have a lathe so I "turned" the parts with a hand drill and made the o-ring grooves with a hack saw blade." To me that sentence exemplifies the can do spirit of a true amateur experimental rocketeer. Anyway, lots of interesting stuff on his site and worth checking out.

Tuesday, May 21, 2013

TR-1 MOTOR UPDATE

Monday, May 20, 2013

TR-1 MOTOR UPDATE

I may still decide to take some excess weight out of the nozzle ring as it's heavier than it needs to be. Then again, it doesn't really matter for the static test so I may just get the important stuff done then move onto the next piece. It would be beneficial to remove weight from the aft end of the rocket before the flight so I'm sure I'll do it before then. I'm machining the nozzle ring out of 1018 which is noticeably tougher to machine than the 12L14 that I'll be using for the divergent piece. Once you've machined 12L14 steel, all other steel seems like a chore!

Labels:

machining,

nozzle,

rocket nozzle,

TR-1 Rocket

Friday, May 17, 2013

TR-1 MOTOR UPDATE

I started on the nozzle ring this morning. I drilled out the center, starting with a center bit and working up to a 1" diameter bit. The larger drill bits remove a lot of material quickly, but an inch is about the limit for my lathe. Next I'll bore out the center to the right diameter. Then I'll face it, cut the relief that the divergent section fits into, and index the holes for the six screws that hold the two sections together. Then I'll flip the piece. Once flipped I can finish it off to the correct diameter and cut the convergent section. Lastly I'll add the o-ring gland and index the twelve screw locations for the screws that hold it in the casing.

Thursday, May 16, 2013

SStS MOTOR CASING (DSS TM-3)

The aluminum tube for the DSS-TM-3 SStS motor arrived yesterday. I'm just indexing/drilling the screw holes so not much work for me. DSS TM-3 motor? OK, it's getting tough to keep track of all the motors as there are more than a few in varies stages of construction and testing. The motor is a single burn (half of the dual phase concept) that is intended to serve as a flight motor for the avionics package once successfully tested. The design calls for approximately 90 lbs (41 Kg) of propellant. Hopefully that flight will occur later this year. As always, check the weekly reports on the Sugar shot to Space site for more detailed information.

CHARLES M. PARKIN, JR.

Charles M. Parkin, Jr. as he is described in the book:

Rocket expert, U.S. Army Engineer, Research and Development Laboratories, Fort Belvoir, Virginia; Founder of Youth Science Corps; President, American Rocket Society, Washington D.C. chapter.

In the later chapters of the book, he describes a small rocket which utilizes a sugar based propellant. I've often thought that it would be fun to build that rocket exactly to the specification in the book and then actually fly it.

Maybe I will do that some day...

Wednesday, May 15, 2013

TR-1 MOTOR CASING

With this drawing, I now pretty much have all the drawings that I need to begin cutting metal in earnest. I plan to go back and update these drawings. I don't really need a drawing for the bulkhead as it's identical to the nozzle ring in thickness, o-ring gland placement, and retaining screw locations.

Monday, May 13, 2013

TR-1 PROPELLANT SEGMENT DESIGN

I plan to use a 4" ULINE mailing tube as the casting tube/inhibitor for this motor. This particular tube has a wall thickness of 0.080" and allows for a bit of insulation to fit between the propellant segments and the casing wall. The motor is designed to use a propellant grain consisting of six segments. Each segment should weigh approximately 4.75 lbs (2.15 kg) for a total propellant load of approximately 28.5 lbs (13 kg).

TR-1 ROCKET MOTOR UPDATE

It been almost exactly one year since I started this motor...far too long. SStS has been going very slowly and in spite of some recent progress, I suspect that the the way forward will continue to be a slow progression. Back when I started getting really involved with amateur rocketry thirteen years or so ago, I was designing, making, testing, and flying much more frequently. I think in those early days, once I joined the Reaction Research Society there was so much excitement in going to the launches. The first event that I went to included zinc/sulfur, LOX/kerosene, HTPB, and sugar . Within the next few months I saw many more of those and added steam, HTP, and a variety of hybrids, good times. I don't know that I can get back to that level of activity anytime soon, but Theo definitely enjoyed the desert, the rockets, and the people so we should make a point to go more than once a year. With that in mind I'm making a conscious effort to finish the TR-1 motor ASAP.

Here is the next part to be made.

This is a fairly heavy motor, but it won't matter. With 1000 lbs of thrust there is no doubt in my mind that it will get itself off the ground when it's time to. The purpose is to build something relatively simple and at low cost, and to sharpen my skills before moving on to a larger project that I've been toying with for the past 10 years or so. There is some excess material in this design, so the part could go through a weight reduction process, but there is really no point for a static test.

Monday, May 6, 2013

SUGAR SHOT TO SPACE SUCCESSFUL FIRING

The Sugar shot to Space project had a much needed successful firing this past weekend. After the spectacular CATO of the impressive DoubleSShot motor nearly one year ago there was a lot of discussion and investigation into what exactly happened and why. This test represents the first in a series that will lead SStS to the successful firing of one of the largest amateur motors of all time. Certainly the largest "Sugar" motor of all time.

Congratulations to Rick Maschek, Paul Avery, and Richard Nakka for their dedication and perseverance, as well as the many other numerous volunteers that have contributed to the project.

Subscribe to:

Posts (Atom)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)