Going through some old photos and rocket related things recently, I came across some photos from 2002. At that time two of the largest motors that I had were designed around two inch diameter "washing machine standpipe" that I found at Home Depot. I decided to try these pipes at the time because they seemed to be very good quality, good/consistent weld, and dimensionally consistent. They also have a thin (0.035") wall thickness which makes for a very lightweight casing. I designed two motors that utilized this casing material. Both motors used identical casings, bulkheads, and closures, but one was designed to use a single unrestricted grain and the other a single restricted grain. The differences in the nozzles are shown in the drawing above. I was concerned about the low initial thrust of the motor that used the single restricted grain and tried to reduce the weight of the nozzle for that motor as much as possible. In the end both motors ended up weighing nearly the same (1.75 lbs). I static tested the unrestricted motor and the numbers correlated closely to the design. Ultimately both motors flew numerous times at the RRS. They were simple to prepare on site (due in part to the fact that each needed only a single grain and that the motor was used as the casting mould). The motors proved to be durable, consistent, and fun to fly.

In the first photo you can see the casing with its nice shiny zinc coating. It is not that shiny from Home Depot, but the finish didn't take much time. Unfortunately the zinc blistered after the initial firing, so the coating was removed with a quick dip in muriatic acid. The 5th photo shows Peter and I taking the rocket out to the launch tower. The 6th photo shows (from left to right) Greg Coleman, myself, Kevin Koch, and Alan Hoyt lifting the launch tower into position. The 7th photo is Kevin, myself, and Alan. The orange and black aeroshell flew a total of five times at the RRS on three different motors. I made it from three inch diameter heavy walled cardboard tube that Kevin found in a dumpster. The fins were cut from quarter inch plywood and were epoxied on to the tube and reinforced with a layer of heavy fiberglass. The nose cone was turned from a block of pine. Eventually, it became too small for the new motors that I was making and was retired. It was always difficult to adjust the tower for it correctly since it had three fins and the tower at the RRS is built for a four fin rocket.

Photos 6-10 were all taken by Tony Richards.

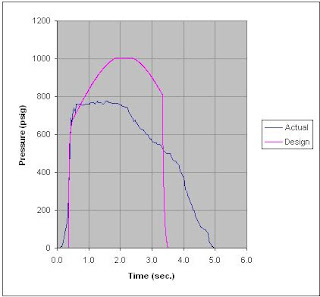

I changed the design again. I decided to optimize the it for KNER propellant by adding two additional segments. The additional propellant brings the motor up to a solid L-class motor and the chamber pressure sims. at right about 1000psi. I'm hoping to have an opportunity to test fire it for the first time in early December

I changed the design again. I decided to optimize the it for KNER propellant by adding two additional segments. The additional propellant brings the motor up to a solid L-class motor and the chamber pressure sims. at right about 1000psi. I'm hoping to have an opportunity to test fire it for the first time in early December