Started work on the after what has turned out to be far too long of a layoff...work and such getting in the way. We got the motor casing cut to length, ends trued, and screw locations drilled. Theo and I are hoping to fire this motor mid September and fly before the end of the year. Pending a successful static firing the plan is to use this motor as a booster for a boosted dart configuration. More on that later...

Showing posts with label n-class. Show all posts

Showing posts with label n-class. Show all posts

Monday, August 25, 2014

Monday, June 3, 2013

TM-3 AND TR-1 MOTOR WEEKEND UPDATE

I finished the motor casing for the P-class SStS TM-3 motor this weekend. Not surprisingly, the 6061 t-6 aluminum tube was much easier to work with than the steel pipe used for the previous DSS test motors. I'm pleased with the casing and can't wait to see the completed motor.

I also managed to get a good start on the divergence half of my N-class TR-1 motor. The 12L14 leaded steel I'm using for this piece is noticeably easier to work than the regular 1018 steel used for the other half of this nozzle. Using some good quality silver and deming bits I was able to remove a lot of material quickly. Well relatively quickly any way. I want to get this piece finished this week so I can get the two halves of this nozzle together.

Labels:

machining,

n-class,

P-class,

SStS,

TR-1 Rocket

Wednesday, May 16, 2012

TR-1 Rocket

With my sons first visit to the desert to view a rocket launch and to help out with the static test of the Sugar Shot to Space's latest motor a few weeks behind us, we've decided to build a rocket. The last new motor that I designed, built and flew was this one:

That was about two years ago and Theo doesn't remember it at all. That was a new motor that used an existing aero shell that had to be extended a bit to fit the new motor. The whole process of designing and building a rocket is fun for me and actually getting out and flying it is the icing on the cake. Since Theo loves tinkering out in the garage as much as I do, we're going to design and build this from scratch. We don't plan on re purposing any existing pieces, other than maybe some of the electronics. While it may take a little more time with Theo's "help". Did I ever tell you about the time I thought he was cleaning up on the other side of the garage but was actually bungee cording my motorcycles together. Despite any setbacks we may encounter, I'm really looking forward to going through the whole process with him. I'll try and document the entire process here.

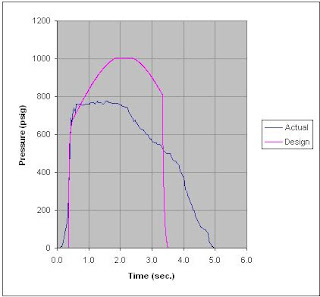

Theo's requirements are that the rocket be big and orange...maybe with some blue. With that in mind the motor is going to be based on this N-class motor that I designed, built, and tested a while back. You can see that motor by going here. The biggest difference is that the TR-1 motor will utilize EMT for the motor casing. As you may or may not know, EMT is one of my favorite motor casing materials. I'm not sure why, I think it's because of other peoples attitudes towards it. I discussed my feelings about EMT, or steel in general during the development of my last motor (the one pictured above), you can read that by clicking here if you're interested. The biggest advantage that I'll get from EMT for this motor is that I can use a standard four inch mailing tube for a casting tube. Four inch EMT actually has an OD of 4.5" and with a wall thickness of 0.083" the ID should be around 4.334". That should allow for a few wraps of rosin paper to be used as an insulator, like I did in the my other design. Though with EMT this isn't necessary for the casing, but will help cut down on the heat transferred to the aeroshell. My initial 4inch motor had and ID of four inches and I was rolling the casting tubes by hand, very time consuming and messy. Using Richard Nakka's "casing" spreadsheet I found that 4 inch EMT has a burst pressure of 2573psi. With a design pressure of 1050 PSI I end up with a design safety factor of 1.7 and a burst safety factor of 2.45, pretty conservative.

I did an initial SRM design, summarized here:

While my previous N-class motor was on the edge of the M/N class this new design ends up solidly in the middle of the N-class and should provide for an awesome experience.

More to come...

Saturday, May 26, 2007

Four Inch Diameter SRM

This is a four inch diameter motor that I've been working on for a while now. This motor is very similar to the motor that I flew last month. Both motors used 6061-t6 aluminum for the casing and 12L14 steel for the nozzle. The grain geometry was also very similar, with the major difference being that this motor uses six segment instead of four. This motor has been fired twice now. Both firings occurred at the RRS's Mojave Test Area. I normally go out to the site the night before to do propellant/motor prep, then sleep in a tent on site that night. The first firing experienced a burn through in the casing. The motor fired well for most of the burn and damage was limited to the casing, so I was very pleased with the initial firing. I made several small changes to the design; first was reducing the diameter of the casting tubes/inhibitor slightly to accommodate an increase in the casting tube/inhibitor thickness of 15% , lastly the casing insulation thickness was increased by 25%. I consider the second firing to be successful. The ignition was a bit slow, due to much of the igniter material being expelled from the nozzle. The use of a pyrogen canister should solve this problem. I am pleased with the resulting ISP of 127 (ISP being a measure of propellant performance). The important thing for me was that the casing temperature didn't begin to rise until several seconds after the test indicating that the insulation was effective. Post test inspection revealed that the insulation had been breached in several places, but the video and temperature data do seem to support the idea that these breaches occurred post firing. I may still add a bit more insulation for added safety though.

Labels:

motor design,

n-class,

rocket motor,

Sorbitol,

srm,

static test

Subscribe to:

Posts (Atom)

.jpg)

.jpg)