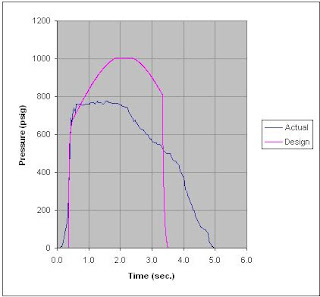

This is a four inch diameter motor that I've been working on for a while now. This motor is very similar to the motor that I flew last month. Both motors used 6061-t6 aluminum for the casing and 12L14 steel for the nozzle. The grain geometry was also very similar, with the major difference being that this motor uses six segment instead of four. This motor has been fired twice now. Both firings occurred at the RRS's Mojave Test Area. I normally go out to the site the night before to do propellant/motor prep, then sleep in a tent on site that night. The first firing experienced a burn through in the casing. The motor fired well for most of the burn and damage was limited to the casing, so I was very pleased with the initial firing. I made several small changes to the design; first was reducing the diameter of the casting tubes/inhibitor slightly to accommodate an increase in the casting tube/inhibitor thickness of 15% , lastly the casing insulation thickness was increased by 25%. I consider the second firing to be successful. The ignition was a bit slow, due to much of the igniter material being expelled from the nozzle. The use of a pyrogen canister should solve this problem. I am pleased with the resulting ISP of 127 (ISP being a measure of propellant performance). The important thing for me was that the casing temperature didn't begin to rise until several seconds after the test indicating that the insulation was effective. Post test inspection revealed that the insulation had been breached in several places, but the video and temperature data do seem to support the idea that these breaches occurred post firing. I may still add a bit more insulation for added safety though.

3 comments:

I just saw your post on the sugpro list and took a look.

This is some sweet motor you got there. Congratulations on it and good luck with your upcoming projects.

Regars,

Magnus Gudnason

www.AIRrocketry.com

Thanks Magnus,

I've seen your site before, very nice stuff there. What happened to your 100mm motor? Looks like it got out of the test stand...

Thanks Randy

Yes it got WAY out.

The bulkead bolts chopped in half probably because of a chamber over pressure.

It is likely that the core pressure shatter the grains on ignition because we RTV´d the grains together so no gas could go around/behind the grains resulting in an uneven pressure (more pressure in the core than around the grains).

We plan on doing another static test in about 10 days or so.

Post a Comment